图片

有人问到:Q

EMDP过热被关闭后,如果受影响一侧的液压压力大于3300PSI,为什么还要关闭相应的EDP呢?

首先,如果你看过我之前的文章:737NG EMDP过热灯亮故障分析应该知道在同一个系统内,EDP和EMDP是共用液压油的,如果EDP本体由于内部磨损发热严重的话,会导致液压油整体温度过高,可能会使EMDP过热灯亮。但是,为什么要用系统液压压力大于3300PSI来判断呢?是因为系统关闭一个液压泵后另一个泵的负载会加大,而3300PSI是EDP能够提供的压力极限,如果超过这个压力,说明EDP超负荷工作,所以需要将其关闭吗?很明显不是,我们看液压泵低压的检查单:图片

关闭一个泵后,就没有提到要检查系统压力啊。其实,这个问题老早之前,写这篇文章的时候,就发现了:EDP 工作原理及故障分析这架飞机当时是左发EDP壳体回油滤单向活门装反,导致左发EDP得不到冷却。我当时译码发现一个现象:图片

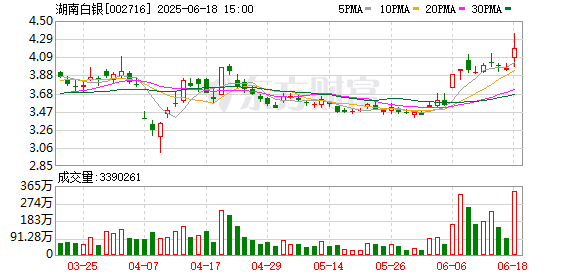

▲A系统压力超过了3200PSI,短时超过3300PSI

事发航段,在EDP低压灯亮之前,A系统压力有很长一段时间超过了3200PSI。

图片

图片

图片

▲左发EDP低压灯亮,机组关闭了EDP,EDP开始持续漏油至20%而排完故后,后续航段压力又回到了正常的水平:图片

▲不接大负载,正常压力2800~3200PSI当时猜想可能是EDP壳体回油受阻的话,会影响EDP的压力输出。图片

从CMM也能看出,EDP输出的压力调节原理:1、泵的出口压力(额定压力3025PSI)与compensator spring的压力进行比较,带动compensator spool朝压力低方向移动,从而给stroking piston供压或者释压,stroking piston移动带动斜盘转动角度变化。2、当泵的输出压力比compensator spring压力低时,compensator spool朝压力低方向移动,stroking piston压力口打开,压力从case drain口放掉,stroking piston移动使斜盘角度变大。3、当泵的输出压力比compensator spring压力高时,compensator spool朝弹簧压缩方向移动,stroking piston压力与泵出口压力相连,stroking piston移动使斜盘角度变小。可以看出,壳体回油如果堵塞,会使阻碍stroking piston移动,从而影响EDP的调压功能。更准确的说,EDP压力往高调节与壳体回油有关。但是,实际中,EDP壳体回油堵塞后会导致EDP的输出压力先正常,随泵温度上升后偏高,再卡阻导致低压灯亮。个人认为,这应该是因为EDP温度升高,会导致其内部压力调节机构无法正常工作。比如Rate piston的弹簧,可能会受热膨胀。从历史记录看,EDP回油堵塞会导致EDP严重过热并最终漏油,送修后发现EDP内部已严重损坏,液压油高温后焦糊碳化。图片

图片

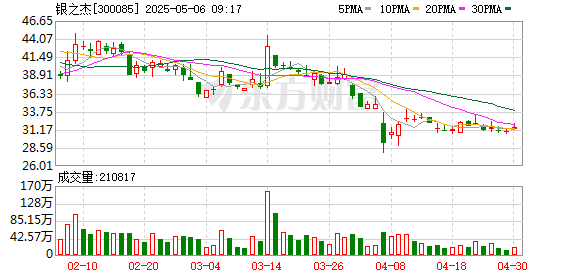

▲液压油碳化后会导致运动部件卡阻与其他工程师交流,他们也发现了类似现象:在所有的EDP壳体回油受阻而导致EDP失效的历史事件中,都译码确认了事发航段的EDP输出压力超过了3200PSI。总之,由于EDP没有过热警告,因此当EDP输出大于3300 PSI时,它可以表示EDP已出现故障,这会导致整个系统液压油温度过高,其具体表现是:输出压力大于3300PSI和EMDP 过热灯亮。所以EMDP过热QRH检查单才会要求首先关闭EMDP,如果系统压力大于3300PSI,还需要关闭EDP。Q

为什么737NG飞机EDP没有过热指示,只有EMDP有过热指示?

我认为原因有2点:首先是EDP不需要过热警告。因为EDP是机械(非电动)驱动的,与EMDP的电马达相比发热量很小。

其次是有也没用。当发动机转动时,EDP始终工作,不能断开或关闭。关闭EDP后泵还会继续运转,但会打开一个释压旁通阀,调节斜盘角度,让泵不往外供压,液压油全部从壳体回油流走。即使EDP有过热警告,关了EDP由于EDP还在运转,系统整个液压油还是会过热,进而还是会导致EMDP过热灯亮。但是相反,EMDP关闭过热以后,就不会再导致EDP过热。

附:1. CMM 29-11-34里的EDP(PN:66087)三种模式:图片

1

Steady System Flow Condition

When a steady system flow condition occurs, there is no system activity and system pressure is at the maximum set pressure. The outlet flow of the pump decreases to zero flow and a compensator spool within the pump is in a stable condition. The spool is balanced by hydraulic pressure applied against one end of the spool and the force of a spring against the other. In this stable condition, the spool blocks about 90 percent of the fluid supply hole that leads to the stroking piston. This causes the stroking piston and the rate piston to be set to keep the hanger bearing surface at a neutral angle. When a neutral angle occurs, the outlet flow of the pump decreases to zero.

图片

2

Increased System Flow Condition

When system activity calls for higher fluid flow, which in turn causes lower pump outlet pressure, hydraulic pressure on the compensator spool is lowered. The compensator spring now moves the spool in the direction of the lower pressure. The movement of the spool opens the fluid supply hole to the stroking piston. Hydraulic pressure on the stroking piston now bleeds to the case drain port while spring force on the rate piston turns the hanger against the lower hydraulic pressure on the stroking piston. The distance the hanger turns, and thus, the angle of the hanger bearing surface, increases as necessary up to a maximum angle where the rate piston stops against the bottom of its bore. With a larger angle, the piston and shoe assemblies move a longer distance back and forth in the cylinder barrel to supply a larger volume of fluid to the system.

图片

3

Decreased System Flow Condition

When system activity and the call for fluid flow by the system decrease, the pump outlet pressure increases. Hydraulic pressure on the end of the compensator spool increases and moves the spool in the direction of the spring. The fluid supply hole to the stroking piston now opens to hydraulic pressure, which causes the stroking piston to turn the hanger towards the rate piston. The angle of the hanger bearing surface now decreases towards the minimum angle and the piston and shoe assemblies move a shorter distance back and forth in the cylinder barrel. The shorter strokes supply less fluid to the system.

2. Vickers EDP:P/N 849589https://www.eaton.com/ecm/idcplg?IdcService=GET_FILE&allowInterrupt=1&RevisionSelectionMethod=LatestReleased&noSaveAs=0&Rendition=Primary&dDocName=CT_195715图片

图片

Internal leakage keeps the pump housing filled with fluid for lubrication of rotating parts and cooling. The leakage is returned to the system through a case drain port. The case relief valve protects the pump against excessive case pressure, relieving it to the pump inlet.

操

作

建

议

通过液压压力监控EDP

可以考虑开发出AHM/WQAR报文专业股票配资论坛,监控液压系统压力。当液压系统压力大于3200PSI超过一定时间后,自动发送ACMS报文,可以提前预知EDP系统故障,检查EDP回油管连接或预防性更换EDP。

本站仅提供存储服务,所有内容均由用户发布,如发现有害或侵权内容,请点击举报。恒瑞行配资提示:文章来自网络,不代表本站观点。

- 上一篇:专业股票配资论坛 震安科技:公司不存在应披露而未披露的信息

- 下一篇:没有了